Design Tips to Maximize Warehouse Efficiency

December 2, 2024 Commercial ConstructionIn this article, we provide essential design tips to maximize warehouse efficiency during the construction process.

6 Design Considerations for Warehouse Efficiency

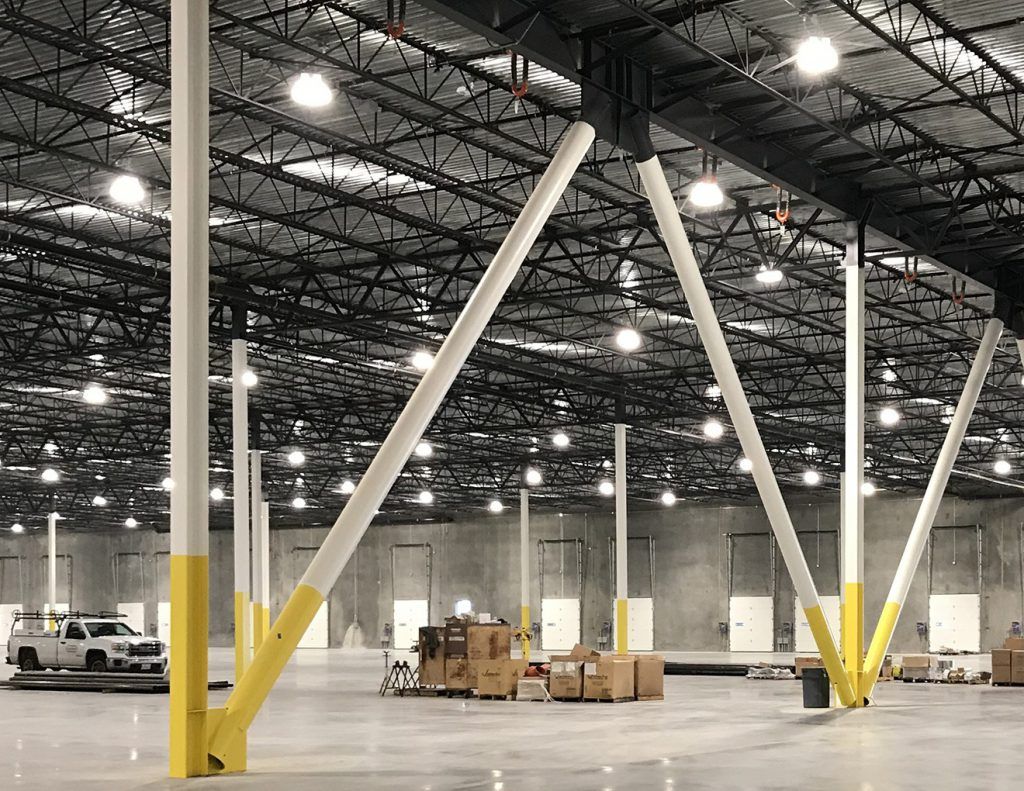

A functional warehouse hinges on efficiency. Designing a warehouse with this in mind is essential for ensuring a safe, streamlined, and cost-effective workflow. From warehouse zones and inventory management to layout shapes, every element must work together to minimize disruptions and optimize operations.

Below, we break down key warehouse design considerations for maximizing efficiency.

1. Establish Warehouse Zones

One of the first steps in efficient warehouse design is establishing a clear workflow by dividing everything into zones. All workflow stages must have their own designated areas within the warehouse to keep inventory organized and reduce congestion points.

Examples of common warehouse zones include:

- Receiving: the first zone where goods arrive from suppliers, also known as receiving docks

- Staging: a rack-free area typically located in front of loading docks, where items are temporarily placed on the floor to be organized or inspected

- Dynamic storage: storage areas with racks for frequently accessed items

- Static storage: storage areas with racks for infrequently accessed items

- Shipping: where items are prepared for delivery and sent out through loading docks

It’s important to establish what zones you’ll need as early on as possible because they will influence future design and layout decisions.

2. Inventory Management and Organization Methods

How you store, organize, and retrieve products has a direct impact on warehouse layout and workflow. These are important to consider early on because they will guide design choices about layout shapes and racking systems.

Below are some common inventory management and organization methods to incorporate in your warehouse design:

- SKU (Stock Keeping Unit): a unique identifying number used by businesses to track individual products in their inventory. Each SKU represents a specific model, color, size, or variation. SKU-based storage can help streamline picking and packing stages.

- FILO / FIFO (First In, Last/First Out): this management method ensures proper rotation of goods for non-perishable (FILO) or perishable (FIFO) items.

- Bulk storage: for items that must be stored in large quantities, such as construction materials or liquids.

Designing your warehouse with these inventory management methods in mind can help streamline workflows and optimize efficiency.

3. Optimize Warehouse Layout Design

To optimize warehouse workflow, you will need to reduce as many inefficiencies as possible with a well-designed layout.

A bottleneck is a congestion point that significantly slows workflow or stops it entirely. To mitigate these inefficiencies, you will need an efficient layout design that best supports your product flow.

Common warehouse layout designs include:

- U-shape: The most common product flow design, which includes a dynamic storage center sided by static storage. Staging and shipping centers are attached to either side of the static storage sections. This layout minimizes material handling and streamlines workflow.

- I-shape: Ideal for long, narrow spaces, this layout sends goods along a linear path from receiving to shipping, ensuring smooth flow and less back-and-forth movement.

- L-shape: This layout also reduces back-and-forth movement as well as traffic congestion by separating receiving and shipping areas in an “L” shape, with storage and staging in the center.

By carefully designing the layout of your warehouse, you can minimize congestion points and ensure smooth product flow.

4. Choose the Right Warehouse Racking Systems

Once you have selected inventory management methods and layout design, you will need to plan which racking systems to use in designated storage areas. Choosing the right racking system will help maximize floor space and keep workflows efficient.

Below are some examples of common warehouse racking systems and key considerations for each:

- Pallet racking: the most common racking system, with rows of pallets and aisles for easy access. This is often used in wholesale club stores and is ideal for high SKU count and bulk storage.

- Drive-In and Drive-Through racking: ideal for high-density storage where forklifts need to drive into the rack. Drive-in is typically used for FILO inventories, while drive-through works best for FIFO.

- Cantilever racking: best for long items like lumber or pipes, but is not space-efficient for smaller goods.

5. Utilize Vertical Space with Mezzanines

In a warehouse, floor space is often limited, so it’s important to take advantage of vertical space whenever possible. A mezzanine is a low story between two main floors in a building, which doesn’t extend over the entire floor space. Mezzanines are highly versatile and allow you to add extra areas like office spaces to your warehouse without sacrificing vital first-floor square footage.

6. Prioritize Warehouse Safety

Safety is an essential consideration in warehouse design, and there are features you can implement to protect workers, minimize liabilities, and avoid costly delays.

- Establish clear aisles and pathways that are obstacle-free and wide enough for safe forklift operation

- Ensure there is proper lighting throughout the warehouse for maximum visibility, which helps reduce accidents and boost productivity

- Design your warehouse to include evacuation paths, clearly labeled emergency exits, and fire safety equipment

By designing your warehouse with safety in mind, you can establish efficient workflows with minimal risks.

Partner With FDC: California’s Commercial Construction Experts

Building an efficient warehouse all begins with careful design. Whether you need an efficient warehouse for your business or want to improve an existing one, the commercial construction experts at FDC are ready to bring your vision to life.

Over the last 50 years, we’ve completed hundreds of commercial construction projects with expertise, efficiency, and great attention to detail. If you’re ready to maximize the long-term success of your warehouse, contact us online today or call (707) 523-1722 to learn more about how we can help.